What is a Gearbox?

A gearbox is a mechanical system that transmits power from a motor to a machine, adjusting the torque and speed through gear reduction or multiplication. It plays a crucial role in optimizing performance, especially in industrial equipment, by matching power output with operational requirements.

Types of Gearbox and Their Applications

Explore the most common gearbox types used across industries, along with their working principles, benefits, and ideal use cases. There are generally 6 main types of gearboxes commonly used across industrial and mechanical applications.

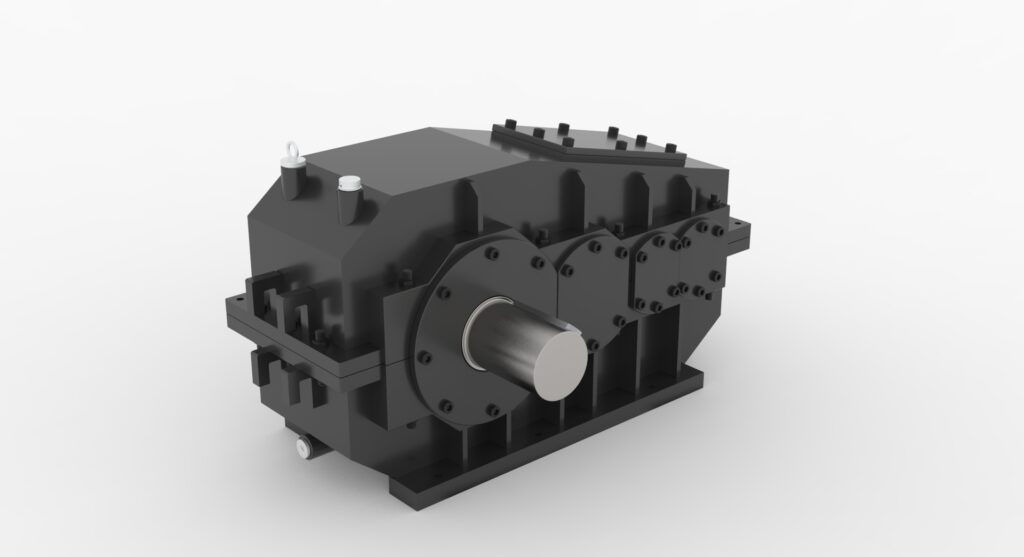

1. Helical Gearbox

How It Works: Uses angled teeth that engage gradually, providing smooth and quiet operation.

Applications:

- Packaging machines

- Conveyor systems

- Extrusion equipment

Advantages:

- Smooth and quiet

- Handles high loads

- Efficient for high-speed operations

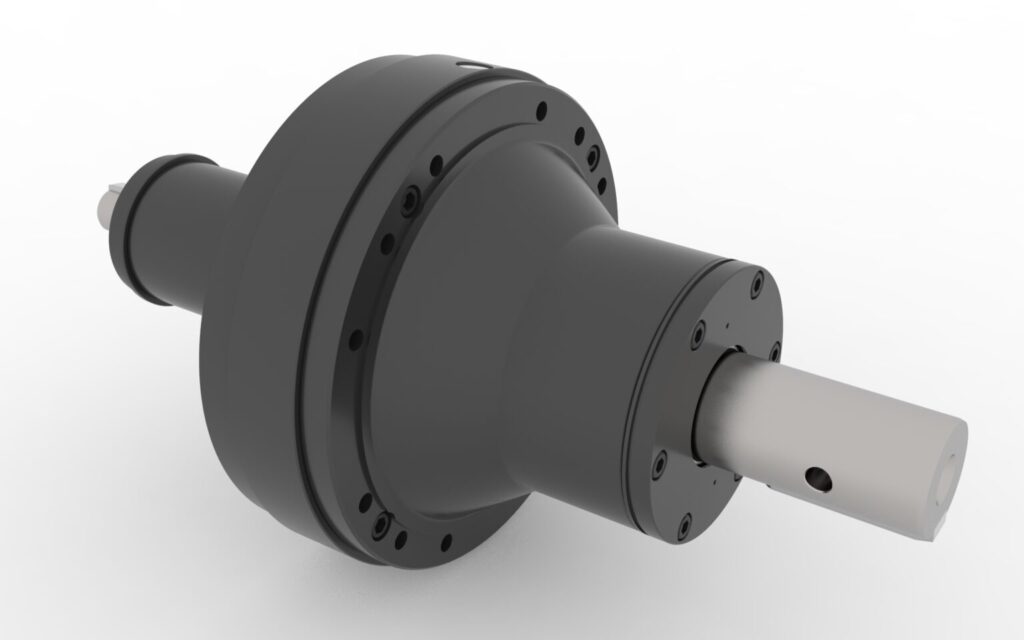

2. Planetary Gearbox

How It Works: Features a central sun gear, rotating planet gears, and an outer ring gear. Distributes load evenly for high torque in a compact design.

Applications:

- Robotics

- Automation systems

- Material handling

Advantages:

- High torque density

- Low backlash

- Compact and efficient (up to 97%)

3. Worm Gearbox

How It Works: A worm screw engages with a worm wheel to reduce speed and transmit motion at 90 degrees.

Applications:

- Lifts and elevators

- Hoists

- Light conveyors

Advantages:

- High reduction ratios

- Compact

- Shock absorbent and self-locking

4. Bevel Gearbox

How It Works: Uses bevel gears to change rotational direction, typically at a 90-degree angle.

Applications:

- Industrial mixers

- Right-angle drive mechanisms

- Agricultural equipment

Advantages:

- Efficient torque transfer

- Flexibility in direction change

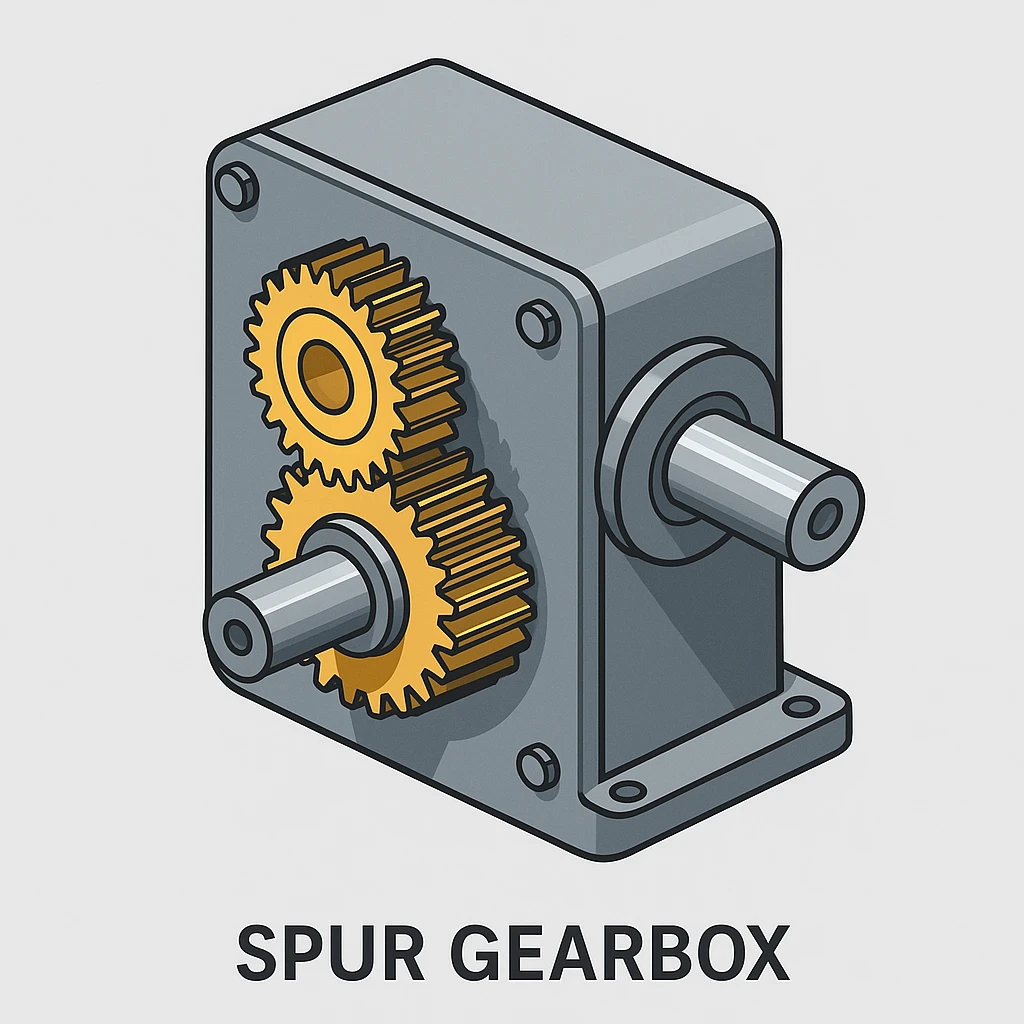

5. Spur Gearbox

How It Works: Straight-cut teeth mounted on parallel shafts. Basic and cost-effective.

Applications:

- Gear pumps

- Printing machines

- Low-speed applications

Advantages:

- Easy to manufacture

- Inexpensive

- Ideal for basic power transmission

6. Cycloidal Gearbox

How It Works: Replaces traditional gears with a cycloidal disc and rollers, enhancing torque and precision.

Applications:

- Servo systems

- Robotic arms

- Precision machinery

Advantages:

- Ultra-compact

- High torque with minimal backlash

- Durable under heavy loads

How to Select the Right Gearbox

When choosing a gearbox, consider the following:

- Required output torque and speed

- Desired gear ratio

- Available space and mounting orientation

- Precision needs and acceptable backlash

- Environmental conditions like heat, dust, and moisture

Conclusion

Different gearbox types serve distinct purposes. Choosing the right one can boost efficiency, reduce downtime, and extend equipment life. At Top Gear Transmission, we provide expert support to match the ideal gearbox with your specific application.

FAQs

Q1: What is the most efficient gearbox type?

Planetary gearboxes are among the most efficient, with up to 97% efficiency.

Q2: Can gearboxes be customized for specific needs?

Yes, at Top Gear Transmission, we offer custom designs based on torque, mounting, and operational requirements.

Q3: What industries use gearboxes the most?

Gearboxes are widely used in robotics, packaging, agriculture, construction, and renewable energy sectors.